This article explores the importance of site wide connectivity.

Construction 4.0 – the fourth industrial revolution refers to the use of new connected technologies to transform and revolutionise the industry.

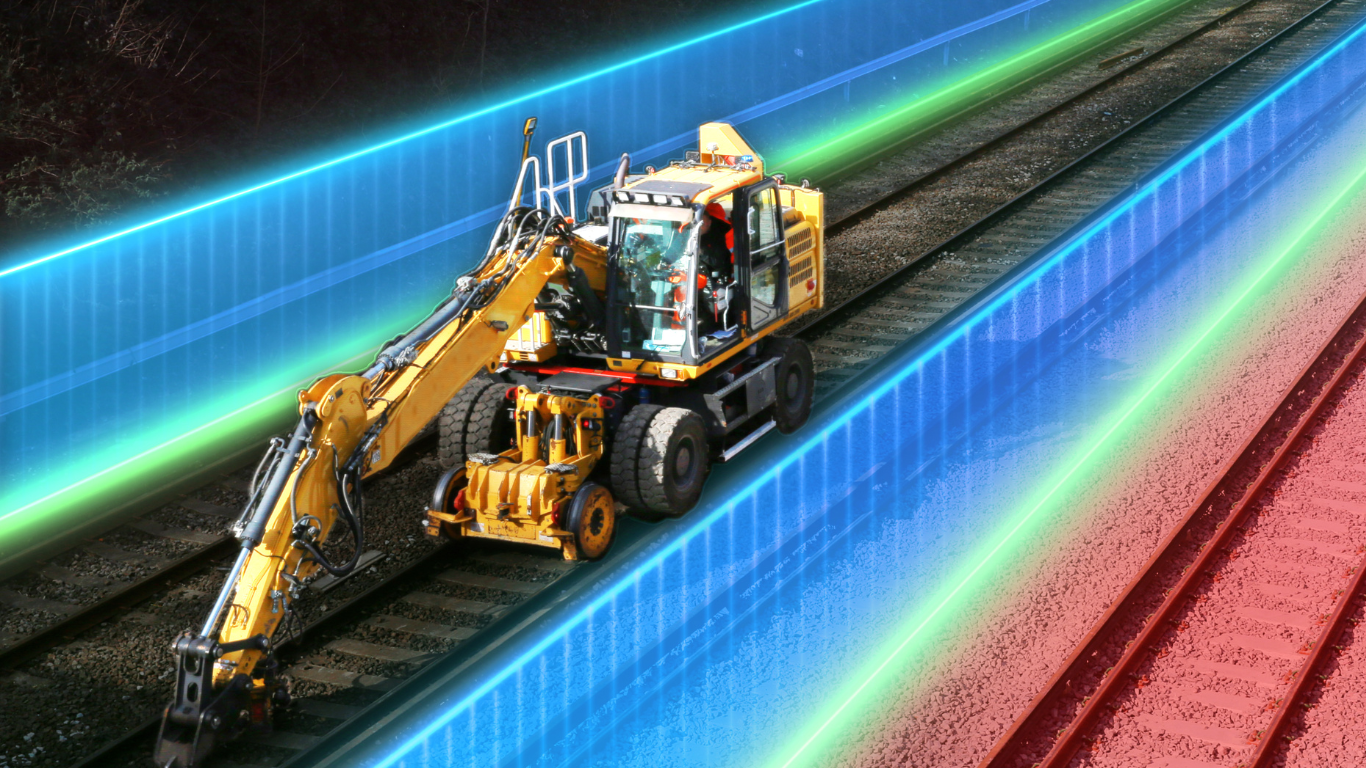

Internet connectivity was historically a basic and relatively simple requirement for construction sites, people on site needed to have portacabin access so that site-based teams could send emails, run basic office tasks, and access the internet. The advent of construction 4.0 meaning an increase in IoT (Internet of Things) and connected devices, BIM (Building Information Modelling) and portable devices has meant that construction sites have the need to be connected site-wide.

Firstly, let’s take a dive into why side-wide connectivity is a necessity for construction sites in 2024.

Why construction needs site-wide connectivity

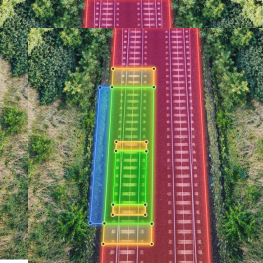

The following is just a small sample of devices, software, and hardware that a construction sites will typically have. All of these will need to be part of the ‘connectivity ecosystem’ and have connectivity.

- BIM

- Vehicle Telematics

- Senors

- Laptops

- iPads

- Smartphones

- Site ManagemenMachine Contro

- Project Management

The number of devices and people on site will typically determine the recommendation for site-wide connectivity.

Furthermore, construction is ripe for disruptive technologies that will transform ways of working from productivity and safety to supply chain management, so the landscape and requirements are rapidly changing and evolving. What we are looking at is a rapid increase in the requirements for construction sites to have quick, robust, and reliable Wi-Fi capability.

UK infrastructure projects such as the National Highways Lower Thames Crossing (LTC) Project are increasingly seeking out technologies to implement and integrate with existing systems. With major construction infrastructure projects like LTC pushing innovative technologies with long term trials to prove how digital transformation can improve value for money and have additional benefit to the contractors they work with – everyone involved is set to benefit in one way or another.

Digital skills and data-based decision making are recognised by Highways England as critical to its future success. Opportunities include the better use of asset condition data to predict and optimise maintenance programmes, and the development of a network traffic simulation tool. -Unlocking Construction’s Digital Future: A skills plan for industry

Improved oversight of public sector productivity could save tens of billions of pounds and deliver better public services despite the current fiscal challenges. In particular, better management of major infrastructure projects and a focus on digital transformation in public bodies would massively improve value for money for the taxpayer.

National Audit Office Head, Gareth Davies

Why the big push for digital transformation?

The construction industry has historically underinvested in technology — only 1.2 percent of its revenue is allocated to IT, compared to a 3.5 percent average across industries. (Source: Deloitte – Digital Construction | Deloitte Central Europe)

Construction projects typically run over time and over budget

Around 69% of construction projects run over budget by 10%. Some of the reasons highlighted include poor allocation of time and resources, environmental factors, overspend on materials and equipment, loss or damage due to technical failures. For example, The Millennium Dome was £60m over budget.

The drive to lower the carbon footprint of construction

The built environment is responsible for around 40% of annual global emissions. This includes running and operations of buildings, construction, and demolition of buildings.

Practical tools for understanding and designing for carbon performance are required. Data and digital technologies, such as digital twins, can be used to improve modelling tools to reduce uncertainty and drive efficiency in design. Data can help to guide decisions about choosing low-carbon materials and processes, enabling better understanding of the carbon impacts at the project level.

Decarbonising construction: building a new net zero industry Four missions to transform and decarbonise the built environment: National Engineering policy centre nepc-decarbonising-construction.pdf (raeng.org.uk)

The environmental component addresses aspects ranging from air quality and energy management to a project’s impact on biodiversity, waste, and water management – all of which needs measuring, monitoring, and reporting on via IoT sensors and smart meters.

Considerations for IT Leaders in Consideration

Typically, IT leaders need to be thinking two steps ahead, and considering how they can adapt and evolve to be ready to embrace the digital tools that construction will be piloting.

The wider considerations will be around being and staying connected and ensuring cyber security is robust.

Social Value

The UK’s Public Services (Social Value) Act, which came into force in 2013, “requires people who commission public services to think about how they can also secure wider social, economic and environmental benefits,”

Digital tools and tech can be used to monitor the impact of social value – understanding, measuring, and reporting on the impact of social value.

Digital construction requires digital skills

Digital construction and the implementation of new technologies require a specific skillset, these will include the ability to understand and use BIM, VR, AI, Robotics and drones.

Roles such as AI architect, Data Analyst, software Developer, Information Manager and Cyber Security Specialist will become more commonplace as the construction sector embraces digital technology.

For example, A survey conducted by ABB highlighted that 81% of construction businesses plan to use robotics in the next decade.

“Land surveying is cut down from two days to 20 minutes now that unmanned aerial vehicles and drones are being used.”

– Director, Tech Specialist

The CITB agreed common definitions and objectives for digital skills, and these showed that construction required people to:

- Think creatively about problems and their solutions

- Understand how to use digital tools

- Assess which tools to use in which circumstances

- Manage the data that flows to and from the use of these tools

Collaboration enable by site wide connectivity

With more projects being allocated to Joint Ventures there are untold benefits to creating opportunities for collaboration.

“There are plenty of good examples, but they’re not evenly distributed across the industry. It is hard to see how they could scale up because an awful lot of the good examples are clearly within the bounds of an individual project or organisation and is it very hard to see how those can be shared across the whole industry”

– Mark Enzer, the former director of Digital Built Britain and strategic advisor on digital transformation at Mott MacDonald.

About Onwave

At Onwave we provide both the connectivity and technology to power digitisation across our customers sites, delivering everything from the communications backbone to custom application development. Get in touch to discover how we’re enabling digital tools for a wide range of construction customers.