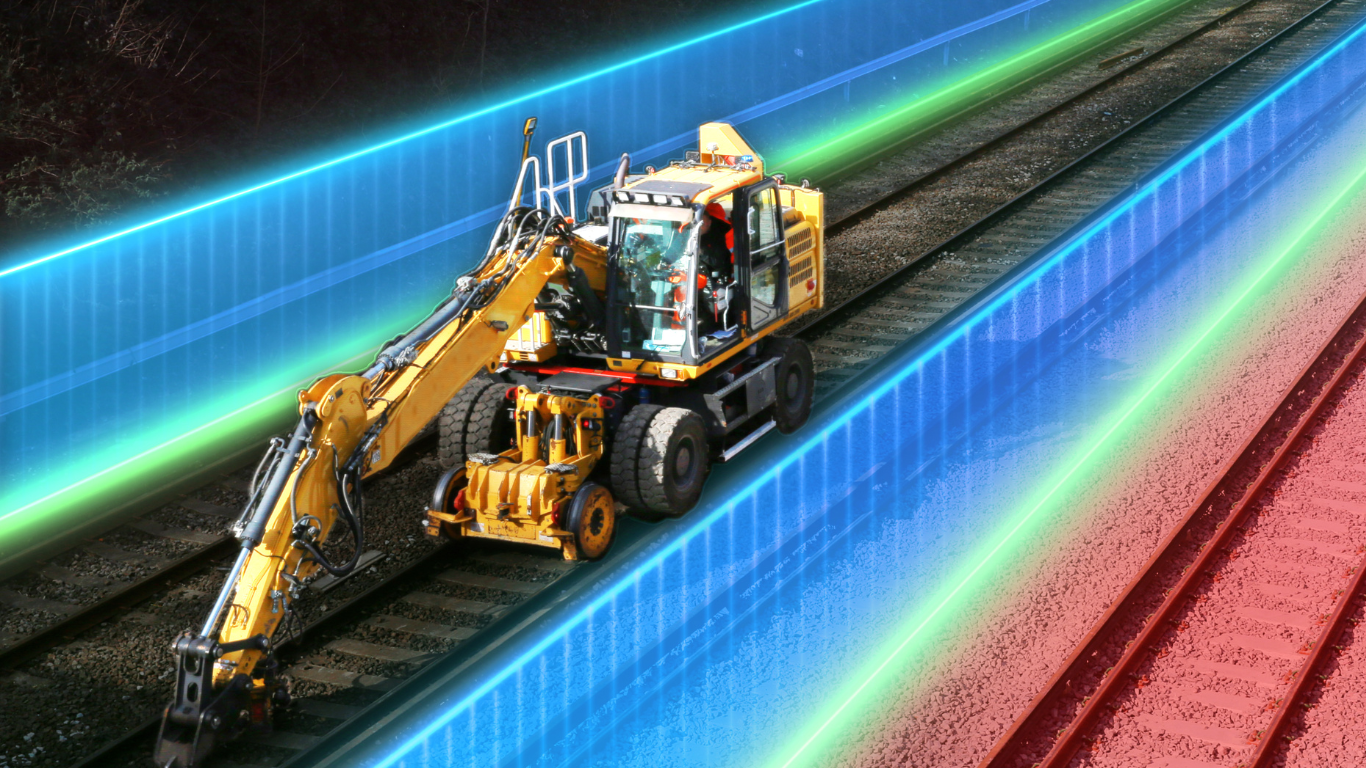

In 2024, the construction industry is poised for a major shift with the increasing adoption of connected autonomous plant (CAP) technology. While the promise of CAP offers many benefits, such as remote data collection, semi-autonomous material handling, and offsite/robotic construction, challenges remain in terms of standardisation, legislation, and investment.

Despite the excitement about the potential of CAP, there is concern about the speed and feasibility of implementation, as well as the associated risks and liabilities.

In this article, we’ll break down some of the current challenges in the market, including legislation, finance and investment, equipment manufacturers, digital and data techniques, and ubiquitous connectivity. By understanding the current state of play, we can better prepare for the future of construction with CAP technology.

The State of Play

The promise of CAP offers many benefits such as remote data collection, geofencing, semi-autonomous material handling, and offsite/robotic construction. However, this transformation presents challenges as there is a lack of a uniform approach and practice varies across sites, clients and manufacturers, resulting in inconsistent deployment and slow information flow.

Despite excitement about the potential of CAP, there is concern about the speed and feasibility of implementation and the lack of direction and investment clarity. The industry faces the risk of investing in new systems without certainty about the technology’s capability and clarity about the associated risks and liabilities.

To help bring all of this together as a snapshot of the industry, we’ve broken down some of the challenges to help understand the current state of play.

Legislation

As with all “autonomous” and “driver-less” technology, there are myriad legislative challenges spanning insurance, ethics, standards and liabilities that have to be ironed out into a usable framework. This covers both safety concerns and also data and cybersecurity challenges involved in the sector.

Our initial impression is that within the next 3 years, we will see new legislation proposed and industry consultations, alongside formal testbeds and reviews, with mandates and maturation of the framework within 10 years. Onwave is working with TRL (Transport Research Laboratory) on a project funded by National Highways to answer many of these regulatory questions to see what needs to be legislated and what can be delivered by industry with a ‘best practice’ approach.

Finance & Investment

Alongside this clear financial incentive, there is a push to prove the quantitative and qualitative benefits of the technology over the next 3 years to then develop incentives and assistance for CAP uptake. We believe this will be reflected in the procurement process to support and reward CAP adoption in the next 7 years. We are seeing early adopters who are wanting to get first-mover status in this exciting new field and the market may well push these targets along faster than the plan

- Government schemes for investment to support CAP

- Funding for academic R&D programmes

- New business models based on CAP opportunity

- A consortium for collaborative investment

- Equipment Manufacturers

As the technology itself already exists and is proven in other sectors, equipment manufacturer focus is largely on the evolving sensors and drones, alongside the data standardisation front as covered below. Over the next couple of years, there will be a push for the development of retrofittable solutions for surveying, control systems for operation, hazard recognition systems and asset recognition capability. There will also be a move toward streamlining the operator control booths and simulators.

The immediate focus over the next 5 years will be semi-autonomous plant, with trials, KPI and hardware being developed to support operator-led functionality with a parallel development of autonomous plant that will begin to become standardised and mandated from 2030. This will all be supported by updates to EN and ISO standards for plant to include autonomy.

Digital & Data Techniques

One of the key challenges of such a cutting-edge innovation is the rush for equipment manufacturers to develop their own intellectual property, which is often at odds with standardisation and interoperable telemetry. Although this technology exists in mining applications and many major manufacturers already have patents for this technology, there is a current drive to understand the telematic protocols and data collection with a view to standardising and subsequently creating new asset registers and construction databases.

Once this is completed, there will be a framework for data sharing, cyber and physical security and new certifications launched based on these new standards internationally

Ubiquitous Connectivity

CAP will require robust and widespread communication capabilities at construction sites.

A review of this is currently underway starting with identifying current and future communication needs and exploring existing solutions. Retrofitting the existing plant will speed up the implementation of this and testbed projects are in progress. Over the next 2 years, we’ll be involved in a deep review of communications infrastructure and analysis of cost-benefits for the comms networks, then designing the framework for this infrastructure post-analysis.

In addition, to ensure secure and reliable remote control or autonomous operation, a review of relevant legislation and regulation will guide the development of communication standards. This will lead to EN/ISO standards for communications, in line with the nationwide rollout of 5G. Local network connectivity is already being established, and there may be a need to allocate transmission spectrum to CAP or utilize space within evolving windows (such as Connected Autonomous Vehicles (CAV) and Connected Autonomous Machines (CAM.)

At Onwave, we understand the challenges facing the construction industry as it navigates the complexities of connected autonomous plant technology. We are committed to providing innovative connectivity solutions that support the successful implementation and operation of CAP systems.

Our expertise in communications infrastructure, data management, and cybersecurity make us the ideal partner for companies looking to embrace the benefits of this cutting-edge technology while managing the associated risks.